7 Reasons To Pre-Press Before A Heat Transfer

Do you really need to pre-press your garment before applying HTV?

It takes up precious time and energy (especially if your press doesn’t open smoothly!), but it is really important!

Let’s take a look at why you should prepare your t shirts for heat transfers by applying heat beforehand!

Pre-Press Before You Heat Press

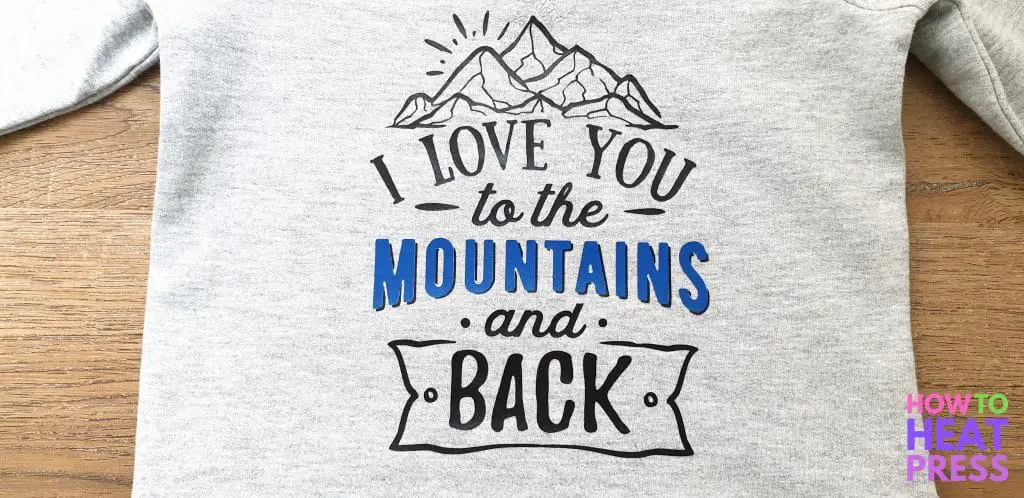

Preparing a t shirt for Cricut Sportflex Iron On

7 reasons you should pre-press garments before applying heat transfers:

- Removes moisture

- Removes wrinkles

- Prepares the fabric for a better print

- Helps the transfer to settle

- Makes for a smoother peel of the transfer backing

- Helps the print to adhere properly

- Pre-shrinks fabric

And let’s delve a little deeper for those of you who still aren’t convinced!

1. Removes Moisture

Perhaps the primary reason for pre-pressing your garments is to remove moisture – in fact, many of the other reasons follow out from this.

Removing moisture from your t-shirts (or other substrates) is so important. Think of it as priming wooden boards for painting, or having a dress rehearsal before a show. Pre-pressing prepares your surface for the transfer.

It doesn’t matter if you are doing a plastisol, inkjet, sublimation or vinyl transfer. All benefit from a good pre-press. If you are pressing t shirts, they are likely produced overseas. Often coming from Tropical areas, and having been sea-borne, they can have a high moisture content.

This does have a very real effect on how your transfers apply to the surface of your t-shirt. Too much moisture and it’s you print may not last well.

Pre-pressing for 3 to 5 seconds, or longer if you are in an area of higher humidity, will ensure a longer life for your product.

2. Removes Wrinkles

Check out these wholesale sublimation transfers!

To state the obvious, pre-pressing removes wrinkles from garments!

It’s important that you press on a flat and even surface so that the transfer applies properly. A loss of pressure in some areas due to wrinkles may cause parts of your design to not transfer (if ink) or lift up (if HTV).

Pre-press to ensure you have a perfect flat surface. You owe it to your transfer.

3. Prepares The Fabric

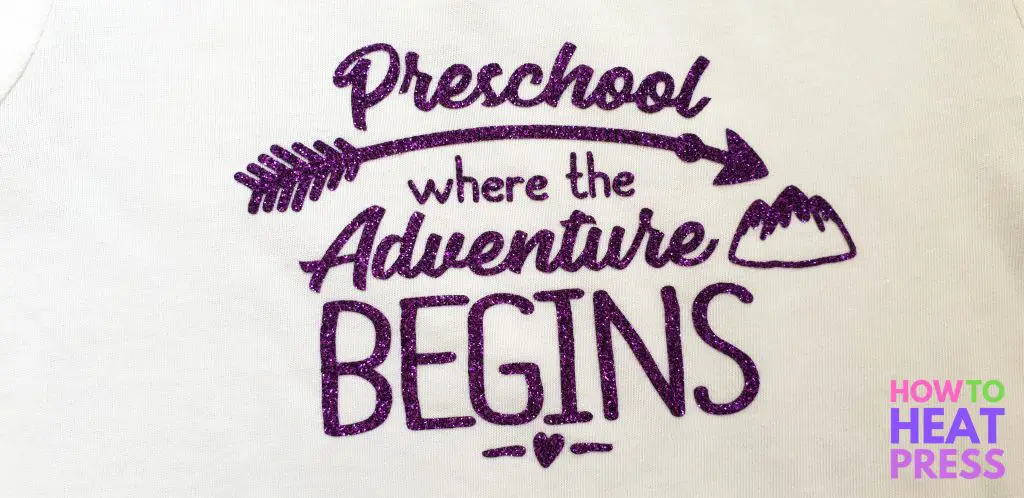

Layered HTV Knee Patches

When you pre-press, your garment is better prepared to receive the transfer – whatever type it might be.

As mentioned before, it is tantamount to priming a board for paint. It is the necessary precursor to pressing – one which, of course, we all wish we could skip!

The dryer a substrate, the better the dyes, vinyl, plastisol, etc, will adhere to the surface, and the longer it will stay on through wearing.

4. Help The Transfer Settle

Imagine trying to write with a felt pen upon a wet page.

Are your strokes likely to settle well upon the page?

No, they are unlikely to settle well!

This is similar to what can happen if you try to apply a transfer, especially an inkjet or sublimation transfer, to a moisture ridden t-shirt.

In extreme cases people experience dyes running or the edges of transfers lifting. If you’re experiencing this the first thing to ask yourself might be, ‘did I pre-press my garment?’

5. Easier To Remove Carrier Sheet

Heat Transfer Vinyl comes away from its carrier sheet when heat is applied. That’s why, when weeding HTV, it’s helpful to warm it up a bit on your heat press.

The carrier sheet will come away easier if the transfer is able to adhere without any moisture.

6. Helps The Transfer To Adhere

At this point I might be repeating myself!

Pre-pressing will help your transfer to adhere. A moisture free and wrinkle free surface allows the transfer, vinyl or dye to bind and become one with your substrate.

I don’t know a whole lot about physics, but suffice it to say, pre-pressing helps your transfer to apply properly.

7. Pre Shrink The Garment

And last but not least, pre pressing help shrink the fabric slightly!

This is especially the case with 100% cotton garments – when heat is applied, there is a little shrinkage. You don’t want this happening when your applying the heat transfers because it will become wrinkled!

How Long To Pre-Press?

Each transfer manufacturer, or transfer paper provider, will have specifications for how long you should pre-press before applying their product.

However, a good rule of thumb is to pre-press for 3 to 5 seconds. Though some people in some places will need to press for 15+ seconds.

The time you pre-press depends a bit on the humidity levels of your area – as alluded to above. If you are in an area of high humidity, like Florida or California then you will probably need to press longer.

Press until you no longer see any steam rising up from your garment – though if this takes longer than 15-20 seconds you may need to put your garments in a dryer first. Pre-pressing longer than 15-20 seconds will run the risk of scorching your garment.

Another idea is to keep a dehumidifier running in your shop or store room. This will help draw the moisture out of your blank/plain garments before it even comes time to press your design in the heat press.

Wood For Heat Transfer

Texprint-r have transfer paper suitable for pressing on wood.

When pressing wood, as with garments, it is essential that it is dry. The key is ink penetration into the wood. This is more likely when the wood is nice and dry. Of course, wood does hold moisture well. It is difficult to dry it out.

Tips for drying out wood:

- Leave wooden items in the sun – though watch out for warping in extreme temperatures

- Let new wood age for at least a year before putting to use

- Leave wooden items for transfer in an area with a dehumidifier

- Pre-press wooden items before transfer

Pre Press Garments

Not pre-pressing your fabrics before heat transfer can cause your work to lift, shift or run. It may mean the transfer will not last so long in the wear and wash cycle of life.

First check your manufacturer’s specifications – this applies to the transfer and substrate. Follow their advice. Beyond this, continue to test and try as you work.

To conclude, you really ought to pre-press to ensure an awesome result – it does make a difference!

Pin this post! 🙂

(Please note: This post contains affiliate links. Read our full disclosure policy here.)